Rin Series

Our Rin Series is based on the kanji 琳, which is the first character in the word Rinpa (琳派); a popular style of painting which started in the Momoyama Period (1568-1600) and became popular in Edo Period (1600-1868). Rinpa-style painting used gold, silver, and other bold colours to express nature in a simple way. Even today, the harmonious link of simplicity and luxury found in Rinpa continues to move people’s hearts. Therefore, when we think of “Rin”, we think of dazzling beauty—which these knives are!

Our Rin Series knives have a blade core made of AUS-10 and a Damascus pattern on the outer steel. The handle is made from oak wood, coated with Urushi - a Japanese traditional lacquer. They draw people's attention like their namesake because of their striking look and traditional Japanese vibe.

Furthermore, they also offer excellent performance. The AUS steels are known for their high rust resistance and ease of sharpening. Normally, these steels need to be sharpened frequently to maintain their optimal sharpness. However, the AUS-10 has relatively longer edge retention compared to other AUSs, so you can enjoy cooking with less maintenance stress!

| Product number | Actual Blade Length (mm) | Full Length (mm) | Total Weight (g) |

|---|---|---|---|

| 1rins-240 | 240 | 390 | 130 |

| 1rins-270 | - | - | - |

| Blade | Material Name | Handle |

|---|---|---|

Double Edged |

AUS-10 | Oak wood with urushi coating |

Sujihiki

Similar to western style Carving/Slicing knives. The Japanese Sujihiki tends to have a little flex and allows for long slices through slabs of meat.

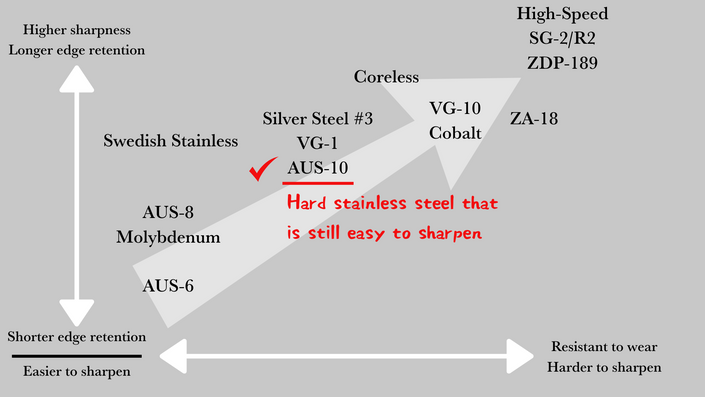

AUS-10

A stainless steel that has high hardness, yet is still easy to sharpen.

Stainless Steel

AUS-10 is a standardized stainless steel with high hardness levels to give it a superior cutting edge, yet is still easy to sharpen thanks to the smaller levels of materials like cobalt, which would normally increase wear resistance.

Clad

Clad knives are made from a steel plate that has a core steel sandwiched between soft iron. It is then shaped, hardened, and polished. This method is often used for knives focused on cost performance, as they are easier to remove distortions form and process.

Damascus

Damascus is a knifemaking technique. It involves layering two types of steel with different hardness levels together to create a unique pattern. The knife is polished after it's shaped, making the harder steel shiny while leaving the softer steel dull, creating a ripple effect that resembles wood grain on the blade's surface. The ripples resemble the ripples of Wootz steel made in ancient Damascus, so the pattern is referred to as Damascus today. This beautiful pattern has garnered a high reputation and is popular in the kitchen knife community.

Optional Engraving

Optional Engraving Service

Sakai Ichimonji provides complimentary engraving using either Japanese Kanji or English Alphabet. Please specify your preference. For details, please visit here

A knife store that has supported the history of knives and food culture in Japan.

It has been 600 years since the birth of swordmaking in the Sakai region of Japan. Sakai Ichimonji Mitsuhide's and it's craftsmen continue to build on that legacy by producing the finest blades in Japan.

This is where the culture of completing a dish of sashimi by "just cutting" and the culture of expressing sharpness as "taste" was born.

For 70 years, we have been connecting the spirit of Sakai's craftsmen with the passion of chefs in Osaka's kitchen equipment shopping district, known as the kitchen of Japan.

We are very happy that our knives can be used by people all over the world.

Precautions

After use, wash off any dirt and wipe thoroughly with a dry cloth to remove any moisture. This product is not for use with frozen foods.This product is handmade, so each piece will be different. Please use the weight and length listed as a guide. Each material is natural and may vary in color. It is not the same as the picture.We take great care with our inventory, but in the unlikely event that we are out of stock, we will contact you by email to let you know.