G-Line Series

Our G-Line Series is used by many chefs domestic and abroad, and we have reliably made and sold it for decades. Many chefs from different cuisines report enjoying G-Line knives thanks to their high hardness levels, long edge retention, and good cutting ability. The VG-1 stainless steel used in G-Line knives is manufactured well, using raw materials with few impurities. With 1% carbon and 14% chromium, this steel is hard, wear-resistant, rust-resistant, and cuts through food seamlessly. These four benefits are what any good blade is measured on, and G-Line rates highly in all categories.

This knife cannot use Wooden Saya.

| Product number | Actual Blade Length (mm) | Full Length (mm) | Total Weight (g) |

|---|---|---|---|

| 1dg-h135 | 135 | 250 | 205 |

| 1dg-h165 | 165 | 285 | 300 |

| 1dg-h180 | 180 | 310 | 350 |

| 1dg-h210 | 210 | 335 | 380 |

| Blade | Material Name | Handle |

|---|---|---|

Single Edged |

VG-1 | Compressed plywood handle with brim |

Deba

Deba knives are often used to fillet fish. The blade is the heaviest of all Japanese knives and is capable of chopping through fish bones and heads easily.Professionals use a 210 mm type to cut Sea Bream and Yellow tail and a 150 mm type to cut small fish such as horse mackerel. For home use, a 150 mm knife is often used.

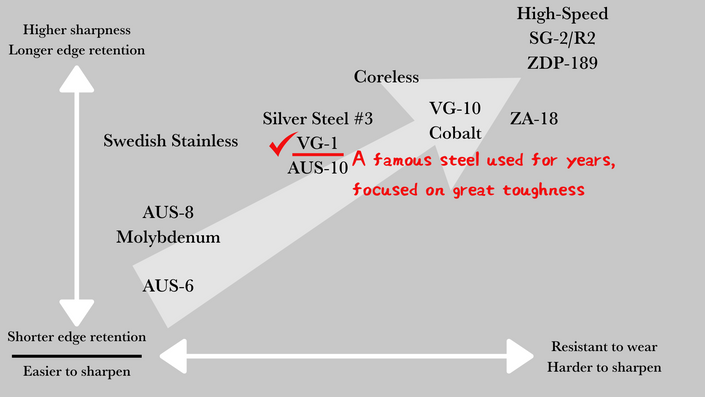

VG-1

A stainless steel with high hardness and long edge retention

Stainless Steel

VG-1 makes its mark as a reliable stainless steel, which we've made knives with for decades. Its key feature is a high hardness level, which also means longer edge retention. A well-made VG-1 knife will have excellent sharpness compared to other stainless steels as the raw materials contain very few impurities. While the high hardness makes sharpening a little difficult, it also makes a knife that can cut well for a very long time. We recommend this steel for people who do longer cutting sessions and don't want to sharpen during those processes.

Compressed Wood

This handle is made of a durable, compressed plywood, with a flange attached to improve balance. It's known for being very hygiene-friendly because water cannot easily get into the core wedged between the handle.

Mono Steel

Mono-steel knives, sometimes called single-steel knives, are made entirely of one piece of steel. Mono-steel knives have better cutting power versus clad and Damascus-finished knives with the same steel material. While mono-steel knives are vulnerable to impact damage, a master artisan can properly quench and remove the steel's distortions, removing this downside while creating a sharp cutting edge.

Optional Engraving

Optional Engraving Service

Sakai Ichimonji provides complimentary engraving using either Japanese Kanji or English Alphabet. Please specify your preference. For details, please visit here

A knife store that has supported the history of knives and food culture in Japan.

It has been 600 years since the birth of swordmaking in the Sakai region of Japan. Sakai Ichimonji Mitsuhide's and it's craftsmen continue to build on that legacy by producing the finest blades in Japan.

This is where the culture of completing a dish of sashimi by "just cutting" and the culture of expressing sharpness as "taste" was born.

For 70 years, we have been connecting the spirit of Sakai's craftsmen with the passion of chefs in Osaka's kitchen equipment shopping district, known as the kitchen of Japan.

We are very happy that our knives can be used by people all over the world.

Precautions

After use, wash off any dirt and wipe thoroughly with a dry cloth to remove any moisture. This product is not for use with frozen foods.This product is handmade, so each piece will be different. Please use the weight and length listed as a guide. Each material is natural and may vary in color. It is not the same as the picture.We take great care with our inventory, but in the unlikely event that we are out of stock, we will contact you by email to let you know.